Innovations in Rotational Molding: Pushing Boundaries in Plastic Manufacturing

Plastic materials have already been an integral part of our daily life for years now. We use plastic material products for a variety of functions, whether it is for packing, saving, or ornamental purposes. When the production of plastic goods has evolved through the years, probably the most Rotational Molding intriguing methods of creating plastic material goods is Rotomolding. Rotomolding is undoubtedly an craft that involves the warming and molding of plastics to produce different goods. In the following paragraphs, we shall dive deep into the field of Rotomolding and discuss the different aspects of the process.

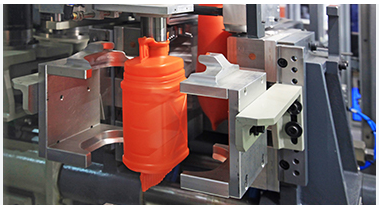

The 1st period at the same time of Rotomolding involves the roll-out of a mold or device. The fungus is normally made of aluminium, metal, or epoxy and is also created in accordance with the needed requirements of your merchandise. As soon as the fungus is produced, it is linked to a spinning left arm within a equipment known as the rotomolding cooker. The uncooked plastic material is then put into the fungus in both natural powder or liquefied form.

The next period requires heating system the mold along with the plastic-type in the oven. The heat during this period differs according to the size of the mildew and the kind of plastic material employed. Generally, the temperature in the oven can vary from 250 to 400 degrees Fahrenheit. Heating system the mold and plastic material to this heat triggers the plastic-type to dissolve and follow the mold.

The 3rd point requires rotation in the mildew to ensure the plastic is consistently dispersed. The rotation from the oven is generally carried out with a velocity of 4 to 20 revolutions per minute. This method helps to ensure that the plastic-type material is equally distributed through the entire mold and there are no atmosphere pockets.

Your fourth period entails cooling the fungus along with the plastic-type. The mold is taken away in the stove when the plastic has solidified and cooled. The cooling procedure can also be carried out manually by utilizing air and h2o. After the plastic-type has cooled, the product is able to be pulled from the mildew. The chilling process is essential because it helps to ensure that the plastic-type material fails to warp or deform.

The very last phase consists of shaping the surplus plastic from the merchandise. This product will then be inspected for virtually any flaws or flaws. As soon as the item goes by the evaluation, it is able to be packed and mailed to its ultimate vacation spot.

In a nutshell:

Rotomolding is a intriguing method that makes plastic merchandise of diverse shapes and sizes. Using this type of procedure, you will find no limitations to the type of merchandise which can be made. The process is cost-effective and guarantees the creation of higher-top quality products. If you are searching to generate a plastic-type material merchandise, Rotomolding is certainly an option you should look at.