Beyond the Ordinary: Exploring Fiberglass Reinforced Plastic Innovations

Fiberglass Strengthened Plastic-type (FRP) has developed into a ubiquitous materials in various market sectors due to the adaptability, longevity, and price-performance. Made up of a polymer matrix reinforced with window fibres, FRP provides a engaging alternative to standard supplies like steel, wood, and cement. Here’s an intensive overview of all you need to know about fiberglass reinforced plastic material.

Formula and Producing

FRP is normally created by impregnating cup materials by using a thermosetting resin, including polyester, vinylester, or epoxy. The fibres supply power and tightness, whilst the resin matrix binds them together and supplies defense against deterioration and environmental factors. The manufacturing approach requires layering the resin-drenched materials into a mildew and letting them get rid of, producing a strong and light-weight composite substance.

Components

FRP exhibits a outstanding mix of qualities that make it ideal for a wide range of software:

Strength and Durability: FRP offers great tensile strength which is immune to rust, chemical substances, and environmental degradation.

Light in weight: Despite its energy, FRP is light in weight, making it very easy to transfer, take care of, and set up.

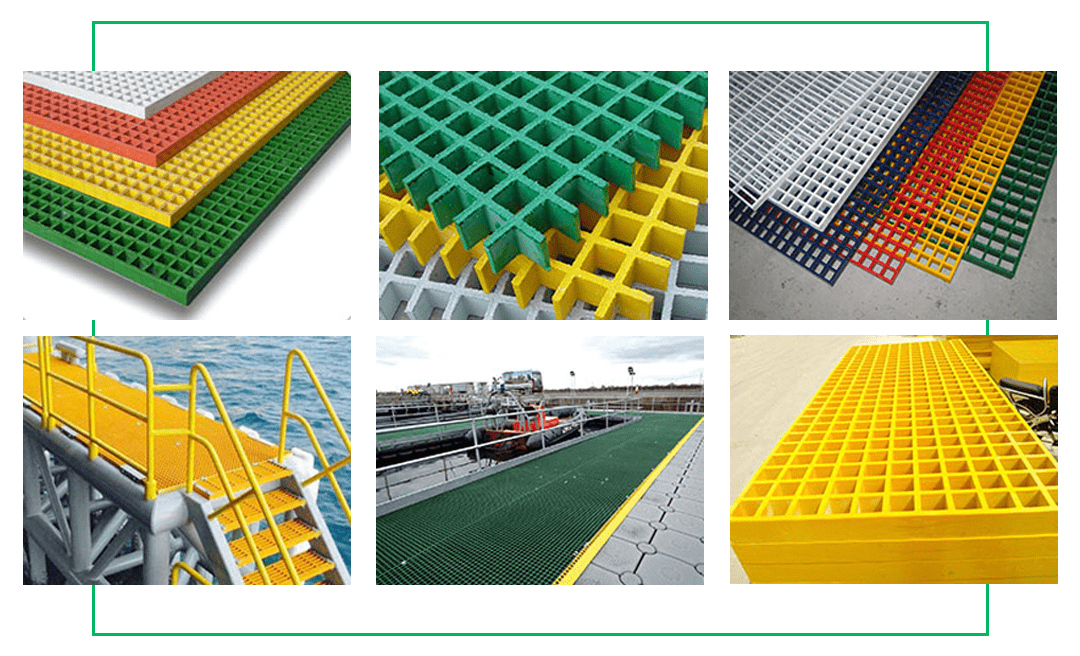

Flexibility: FRP might be shaped into a variety of styles and sizes, allowing for sophisticated patterns and customized alternatives.

Insulation Components: FRP is a great insulator of electricity as well as heat, rendering it ideal for software where thermal or electric powered conductivity is a concern.

Low Upkeep: FRP demands minimal upkeep in comparison with conventional resources, lowering long term fees and down time.

Applications

The flexibility of FRP gives itself to a variety of programs across distinct sectors:

Design: FRP is utilized in constructing factors such as panels, cladding, and roofing systems for its durability and conditions resistance.

Transportation: FRP finds applications in car, aerospace, and marine businesses for light in weight factors for example entire body panels, plane decorations, and vessel hulls.

System: FRP can be used in bridges, pipelines, and tanks due to its rust resistance and structural dependability.

Resources: FRP is employed in power and telecommunications facilities for its insulation components and durability.

Summary

plastic grating Reinforced Plastic is a flexible and durable materials that will continue to find innovative apps across different sectors. Its mixture of power, toughness, and price-performance causes it to be a engaging option for designers and designers trying to find substantial-overall performance alternatives. As modern technology advances, FRP is probably going to engage in an even more substantial part in shaping the way forward for production and development.